Understanding Micropile Load Test: An Essential Guide for Foundation Stability

Micropiles play a critical role in foundation support systems, especially in areas with challenging soil conditions or where traditional foundation methods may not be feasible. These small-diameter, high-capacity piles are often installed in tight spaces and used for a variety of projects, from underpinning to new construction.

A micropile load test is essential to verify that micropiles can support the intended loads safely and effectively. This test measures the capacity of the micropile under actual site conditions and ensures that it will perform as expected. Through precise procedures, such as the micropile load test procedure and micropile tension load test, engineers can determine the load-bearing capacity and overall structural stability, ensuring that the foundation is safe for long-term use.

Ensure Your Foundation’s Stability with Expert Micropile Load Testing – Schedule Your Consultation Today!

What is a Micropile Load Test?

A micropile load test is a method used to assess the load-bearing capacity of micropiles. It is a crucial process in foundation projects, ensuring that the micropiles can withstand the required loads under real-world conditions. These tests measure how much weight a micropile can support, helping to avoid potential failures and costly repairs.

Load testing is often required in situations where soil conditions are uncertain or where the project requires a high level of structural assurance. Different types of load tests are performed depending on the project’s needs, including compression load tests and micropile tension load tests. These tests help determine whether the micropiles can handle compressive loads (downward pressure) or tensile loads (uplift forces).

Why Micropile Load Testing is Crucial for Structural Integrity

Performing a micropile load test provides several important benefits, most notably validating the pile’s ability to support the required loads. In construction projects, this is essential to avoid structural instability. Load tests allow engineers to measure the actual performance of micropiles in the field, offering assurance that they meet safety standards.

In situations where micropiles may be exposed to uplift or tensile forces, a micropile tension load test is particularly important. This test helps ensure that micropiles will remain stable even when subjected to forces pulling them upwards, which can occur in high-wind areas or when water tables fluctuate.

Micropile Load Test Procedure

The micropile load test procedure involves several key steps to ensure accuracy and reliability. Below is a breakdown of the typical procedure:

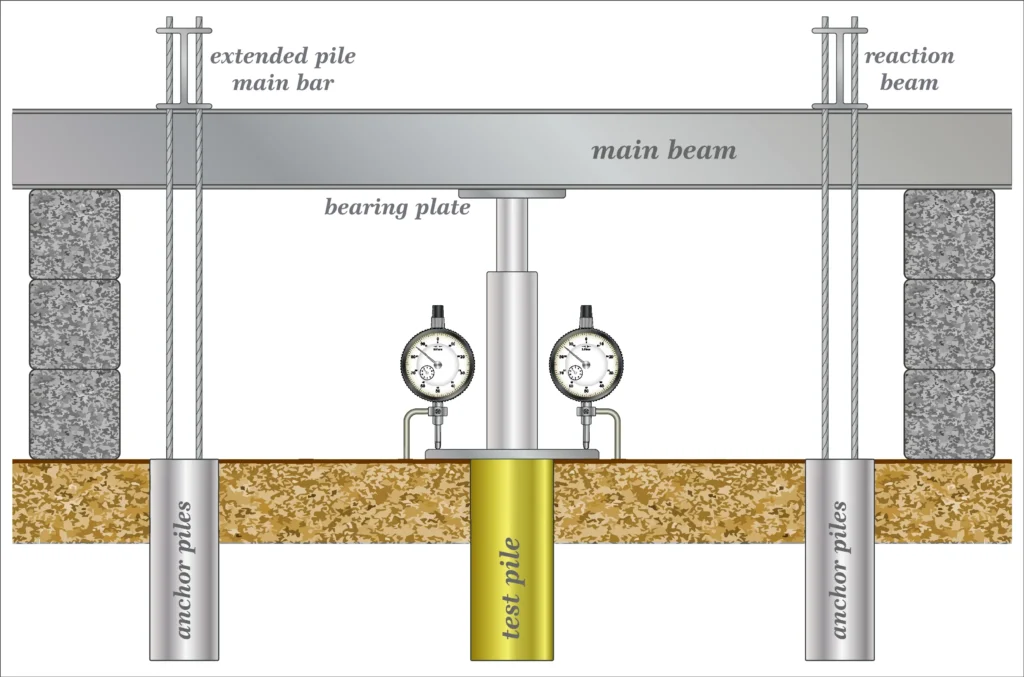

- Site Preparation and Equipment Setup: Before the test begins, the site must be carefully prepared, ensuring that the micropile is properly installed and that testing equipment is calibrated. This includes securing the micropile and setting up load-testing equipment, such as hydraulic jacks and load cells.

- Conducting Static and Dynamic Load Tests: Static load tests apply a gradual increase in load over time to assess the pile’s load-bearing capacity. Dynamic load tests, on the other hand, involve applying a sudden force to measure how the micropile responds to impact loads. Both tests provide critical insights into how the micropile will perform under different conditions.

- Measuring Load Capacity, Displacement, and Safety Factors: During the test, data is collected on the amount of displacement (movement) of the micropile under the applied load. Engineers use this data to calculate the pile’s load capacity and safety factors, ensuring that the micropile can handle both short-term and long-term forces. Detailed safety protocols are followed throughout the process to ensure the accuracy and safety of the test.

This procedure allows contractors and engineers to assess the actual strength and reliability of the micropiles used in a project, providing valuable data to guide design decisions and ensure long-term stability.

Micropile Tension Load Test: Ensuring Stability Under Tensile Loads

A micropile tension load test is an essential part of the foundation testing process, particularly when a project is subjected to uplift forces. Uplift forces can occur in areas with high water tables, seismic activity, or when the structure is exposed to high winds. This test evaluates the tensile strength of the micropiles, ensuring that they can resist forces that pull the pile upwards, preventing structural failure.

Conditions Where a Tension Load Test is Required

A tension load test is necessary for projects where foundations are exposed to uplift forces. Some examples include:

- Buildings in high-wind zones, such as coastal or open areas.

- Structures near large bodies of water where groundwater fluctuation can cause upward pressure.

- Retaining walls or tall structures subjected to lateral loads and forces that can create tension on the piles.

In these situations, a micropile tension load test ensures that the piles are designed and installed to resist the forces acting to pull them out of the ground.

How a Micropile Tension Load Test is Performed and Interpreted

The tension load test follows a systematic approach, similar to other load tests but with a focus on tensile forces:

- Site Preparation: The testing area is secured, and specialized equipment is installed to measure the tensile capacity of the micropile. Anchors and hydraulic jacks are set up to apply upward force.

- Application of Tension: Hydraulic jacks apply an upward force gradually to simulate the uplift conditions the micropile will face during its lifetime.

- Measurement and Data Collection: Throughout the test, displacement (movement of the pile) is monitored to determine how much force the pile can resist before significant movement occurs.

- Interpretation of Results: Once the tension load has been applied and the data gathered, engineers analyze the results. If the micropile moves within acceptable limits under the applied force, it is considered to have passed the test. If excessive movement occurs, it indicates the need for corrective action, such as additional piles or design adjustments.

The results from this test provide crucial insights into the performance of the micropile and whether it meets the necessary safety and load-bearing standards.

Factors Influencing Micropile Load Test Results

Several factors can influence the results of a micropile load test, affecting both tension and compression performance:

- Soil Conditions: The type of soil surrounding the micropile plays a critical role in determining its load-bearing capacity. Soft, loose, or highly compressible soils may reduce the effectiveness of the micropile, while dense soils can provide more support.

- Equipment: The accuracy of the test depends heavily on the calibration and proper setup of load-testing equipment. Inaccurate measurements can result from equipment malfunctions or misalignment during installation.

- Project-Specific Considerations: The design loads, expected duration of the load, and environmental conditions (e.g., seasonal soil movement or water table fluctuation) all impact the outcome of the test. Engineers must consider these variables when interpreting test results and making project decisions.

Interpreting Micropile Load Test Results

The data gathered during a micropile load test provides engineers with the information needed to assess whether the micropile is performing as expected.

- Displacement: One of the primary factors analyzed during a load test is the displacement of the micropile under the applied load. Minimal displacement suggests that the pile can handle the load safely, while excessive movement indicates that the pile may not provide adequate support.

- Load Capacity: Successful results confirm that the micropile can support the expected load with an acceptable safety margin. If the test indicates that the pile is insufficient, engineers must explore alternative solutions or adjust the pile design.

- Guiding Project Decisions: Test results are critical in making informed decisions about the foundation system. If the micropile tension load test shows that the pile can withstand uplift forces, the design can proceed confidently. In contrast, a failed test may require additional piles or deeper installations.

Final Thoughts: Ensuring Foundation Safety with Micropile Load Testing

Both compression and micropile tension load tests are essential to ensuring the long-term stability and safety of micropile foundations. These tests provide critical data that helps engineers design foundations capable of withstanding various forces, including compression and uplift.

Selecting a qualified contractor to conduct these tests is crucial for the success of any foundation project. Proper testing ensures that your foundation system meets all safety requirements and performs reliably over time. If you need expert micropile load testing services, reach out to a professional contractor to schedule a consultation and ensure your project is on solid ground.